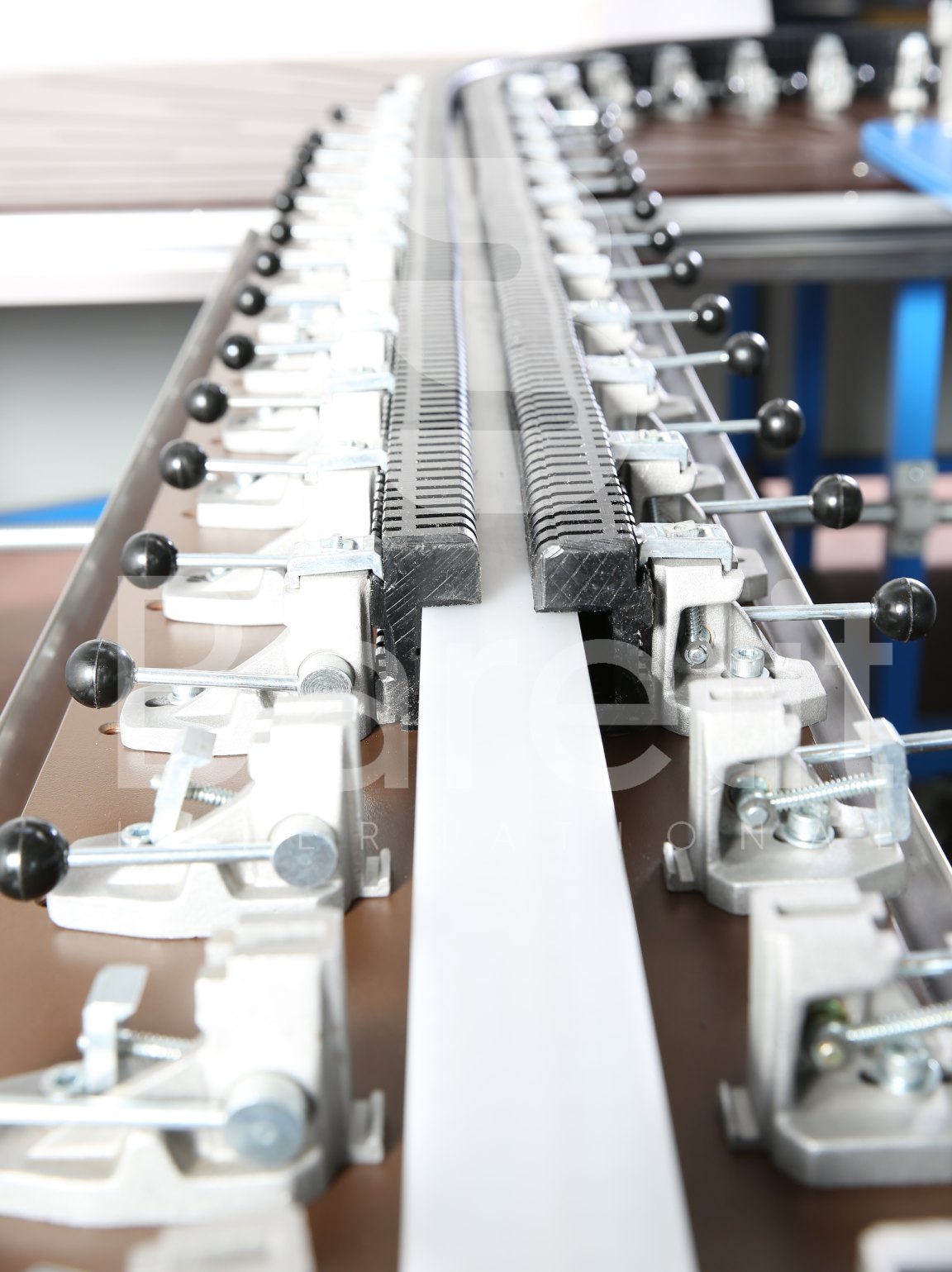

The bending (arch) machines we produce allow bending PVC profiles of any shape and complexity by moulds made individually for each type of profile.

Profile bending is carried out by softening them either in a glycerine bath, or in a technologically new way - in a chamber with heated air. The second method has been particularly popular in Europe lately due to its ease of use, environmentally friendly production and safety for workers.

We produce two types of glycerine profile bending machines – manual and motorized. With manual machines it is possible to bend 3m profiles, while on motorized machines it is possible to bend up to 6m profiles.

The hot air bending machine can also bend 6m profiles.

For high-quality bending, a non-corrosive working table and plastic moulds are required, which do not delaminate and do not crack from frequent heating. In this area, we work with leading German manufacturers, from whom we purchase materials made from high-quality raw materials.

A COMPLETE SET OF MOULDS FOR THE BENDING MACHINE:

Frame

Casement/ Sash

Mullion

Single glass glazing bead

Double glass glazing bead

The length of the moulds is 3000 - 4000 mm.

For the manufacture of moulds, PVC profile samples 1.5 m long are required.