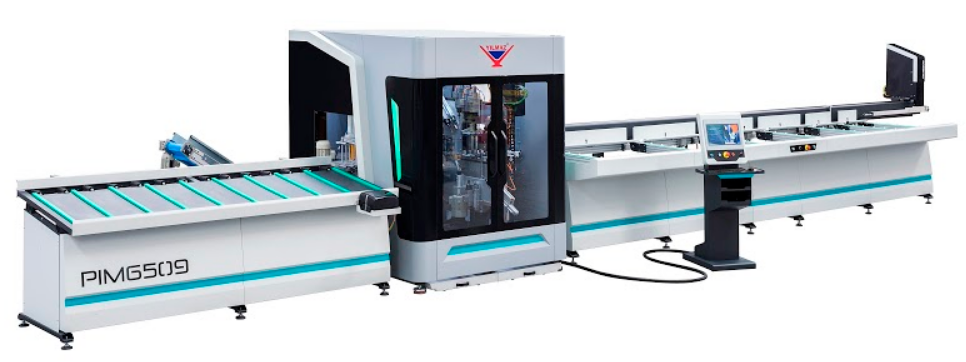

GENERAL FEATURES

Yılmaz custom profiles cleaning program

Manuel and automatic operating modes

Automatic sash and frame profile recognition system

Profile width and height measurement system

11 set of automatic profile cleaning knives

Separate cleaning knives for color and white profiles

Automatic bearing lubrication system

Window-based touch screen

Profile program transfer via USB flash memory

Remote connection and technical support capability

Movable control panel

Speed change during the process

220 frames / 8 hours (608 CNC) and 270 frames / 8 hours (CNC 610)

Visible of screen alarms and warnings

Phase control system

Low-pressure control system

Ability to clean all four corners and end-of line transfer with an automatic rotation robot system

An automatic system allowing movement in three axes (X, Y, Z)

Automatic transition feature between 0.2 and 2 mm welding range, specific to Yılmaz machine

Automatic operation mode integrated with barcode reader or manual operation as per entered dimensions

Lame sash door welding

Capable of entering the welding parameters on the screen and storing them

Fast and easy teflon replacement feature

Ability of creating 1000 pieces of profile recipes

Monitoring of processing times during the operation

Easy placement of long size profiles on the welding unit

mm or inch operation system modes

Max square dimension that SA 260 machine can be rotated is 2000 x 2200 mm. The squares that are having larger dimensions are rotated manually during the welding operation

OPTIONAL ACCESSORIES

SA 251 Window Buffer Station