GENERAL FEATURES

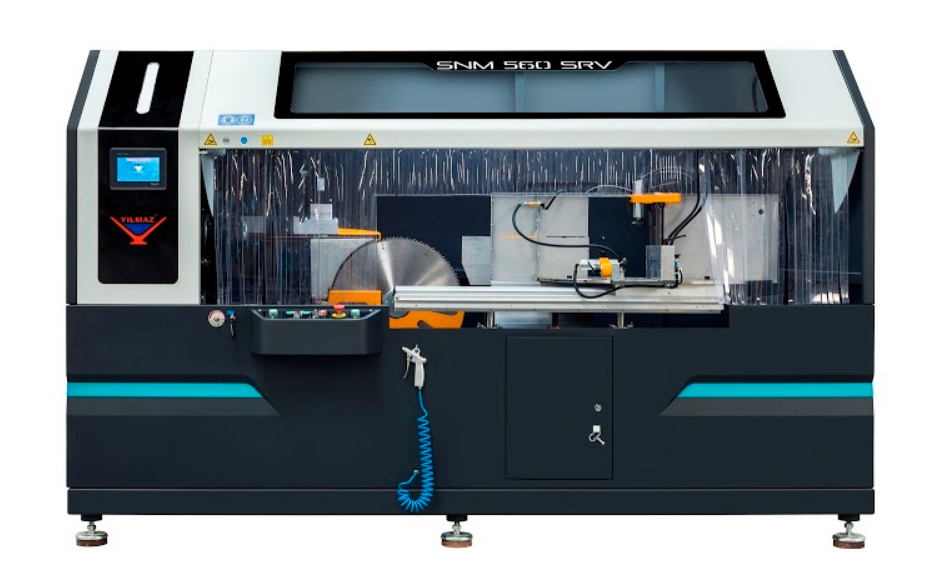

High quality end milling operations by means of the adjustable motor speed thanks to the inverter and potentiometer

Practical change of cutter provides ease of operation

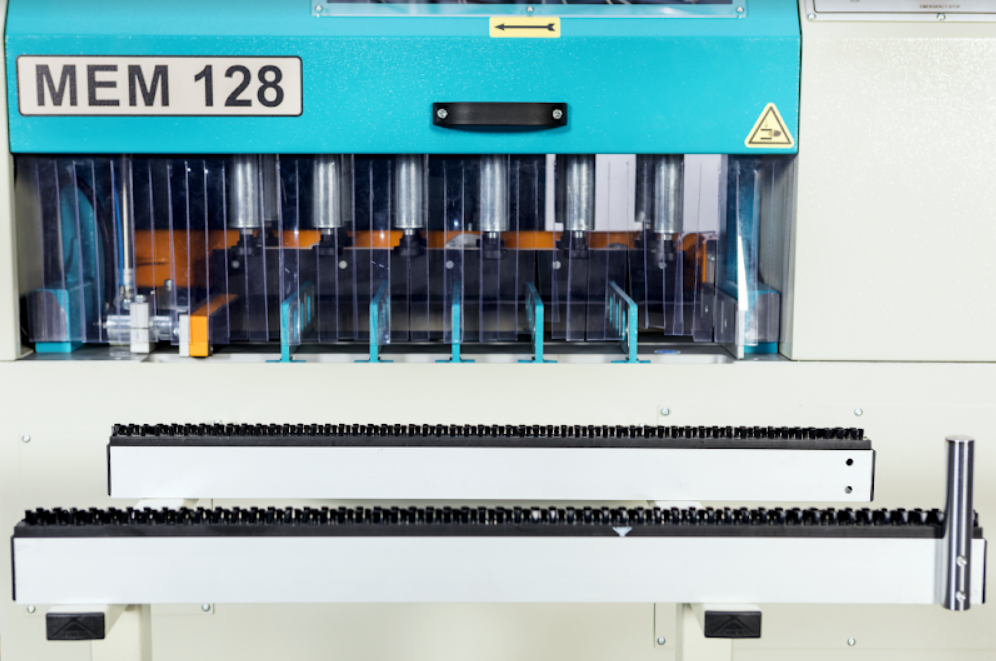

End milling of 1 to 6 sash and frame profiles

Fixing the workpiece firmly and at square by means of the vertical and horizontal clamps

Safety operations with safety guard

Cutter storage location in front of the machine

Robust machine stand and support arms in front of the machine to provide end milling of profiles up to 2.5 meters

Practical cutter adjustment by means of the gap parts

Spray tool lubrication system

end milling profile height (H): 210mm

end milling stroke (W): 615 mm

saw blade diameter: Ø 185 mm

tool height: 150 mm

STANDARD ACCESSORIES

12 x pneumatic vertical clamps with adjustable pressure valve

Horizontal clamp set for fixing the profiles firmly

Air gun

OPTIONAL ACCESSORIES

Milling cutter set

Double pressure clamping