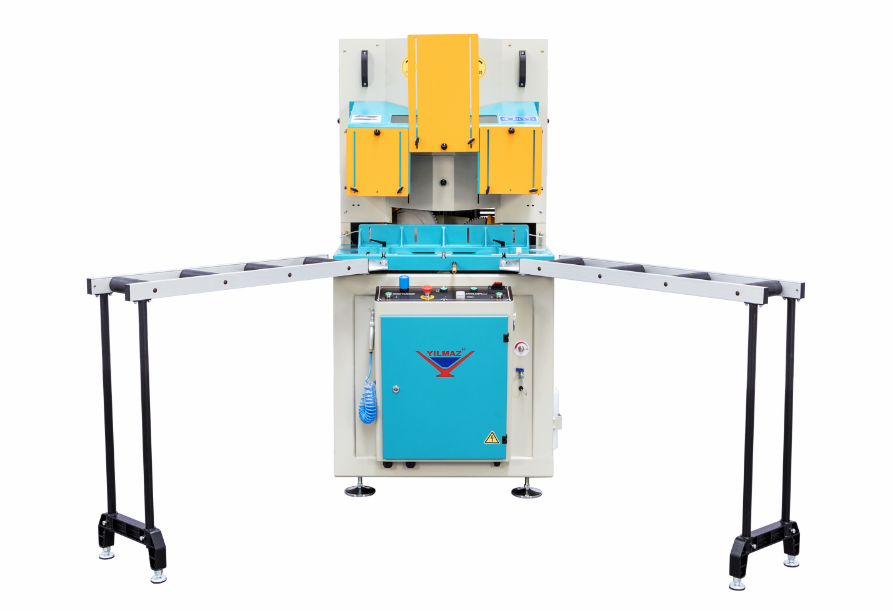

GENERAL FEATURES

Manual upward saw stroke

The back fence is adjustable to allow the most effective use of the saw blade capacity for wide and flat profiles

Location points at 60°, 45°, 30°, 22.5°, 15°, 0° for both left and right

Wide-angle cutting range up to 60° to the right and 60° to the left

Adjustable machine working direction by means of rotatable (360°) platform via. foot pedal

Changing the saw blade ease

It has the ability of lateral and longitudinal cutting operations

STANDARD ACCESSORIES

Equipped with saw blade Ø 420

Back fence

Profile end support

Machine with Ø 450 mm of the saw blade (MK 450)

Spray saw blade lubrication system (MK 420 PS)

2 x mechanic top clamps (MK 420)

2 x pneumatic top clamps (MK420 PS)

Safety guard for lateral cutting operations (MK 420 PS)

Safety guard for longitudinal cutting operations (MK 420 PS)

OPTIONAL ACCESSORIES

MKN 300 roller conveyor (3m)