GENERAL FEATURES

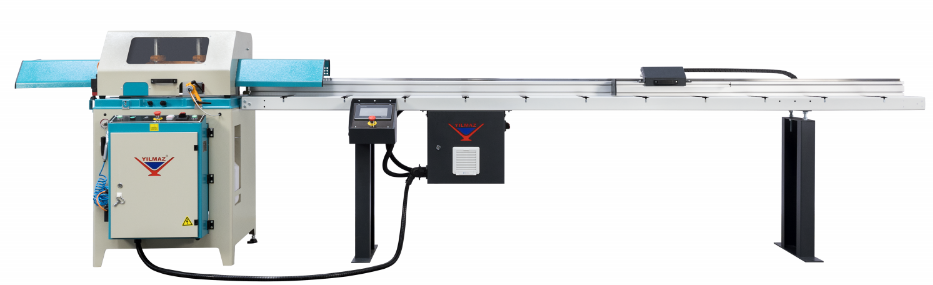

Suitable for high-volume slicing of aluminum profiles for window manufacturing and industrial applications

Precise measurement with mechanical gauge integrated with digital display

Top-blowing unit ensures the table stays free of burr

One, two or three strokes are possible by means of selection switch

Horizontal and vertical clamping of the workpiece during the sawing operation

The machine shut down automatically after reaching the requested quantity

Spray saw blade lubrication system

3 meter of profile roller conveyor

Last remaining waste: 85 mm

Standard equipped with downward motion saw blade

Feeding distance per cycle: min. 5mm / max. 280mm (unlimited for the maximum cutting length

Clamping capacity: : 5, Hmax. :120 / Wmin. :5, Wmax. :200mm

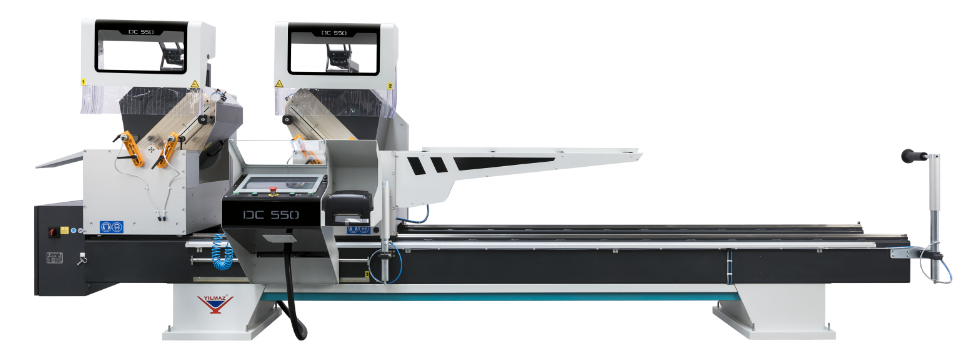

The cutting capacity doubles by two steps of high-speed serial cutting mechanism (patented)

STANDARD ACCESSORIES

3 meter of roller conveyor

Equipped with saw blade Ø 400 mm

Spray saw blade lubrication system

Air gun

4x horizontal clamps

1x vertical clamps

OPTIONAL ACCESSORIES

Extending kit for 6 meter of infeed roller conveyor

Additional saw blade with Ø 400 mm

VCE 1570 Chip vacuum extractor