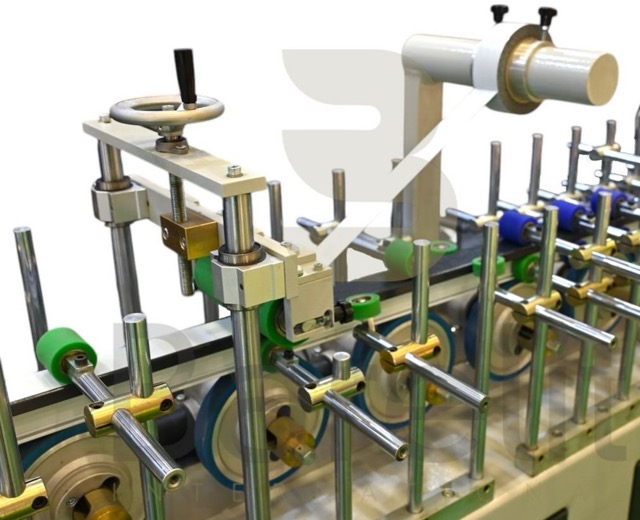

The Automatic Foil Splicing Module with Double Roll Unwinding Station is designed to save time by enabling a continuous lamination process, ensuring seamless production without interruptions.

Time-Saving Features:

1. Continuous Lamination Process:

• Automatically switches from the depleted roll to a new roll without halting the lamination process.

• Prevents downtime, maximizing production uptime.

2. Automatic and Manual Modes:

• Automatic Mode: Automatically switches to the new roll when the current roll is finished, maintaining continuous lamination.

• Manual Mode: Provides flexibility for operator intervention when needed, ensuring roll replacement in specific situations.

3. Fast and Accurate Splicing:

• Integrated splicing mechanism ensures quick transitions between rolls.

• Eliminates manual intervention, reducing delays.

3. Dual Roll Preparation:

• Allows preloading of the next roll, so the system is always ready for immediate switching.

• No need to pause the process to load a new roll.

4. Automation for Efficiency:

• Automatic mode handles roll changes seamlessly, saving operators valuable time.

• Manual mode is available when specific adjustments are needed, ensuring flexibility.