GENERAL FEATURES

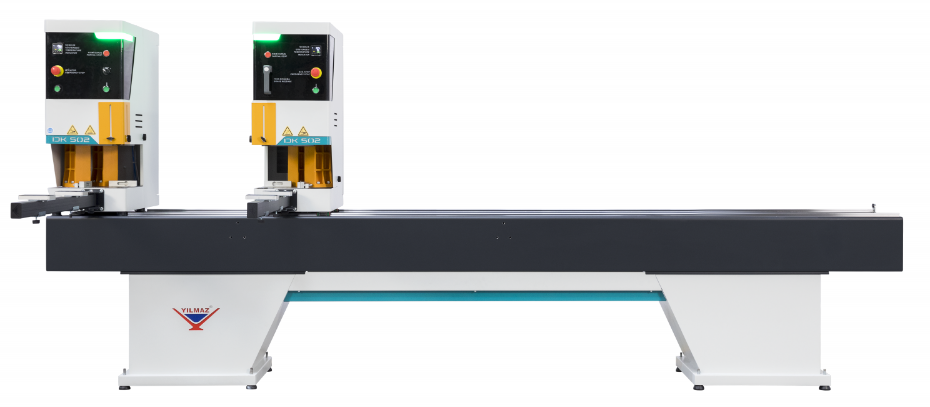

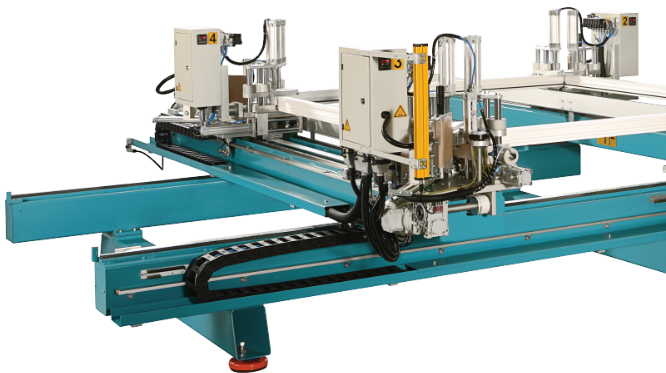

Fully automatic two corner welding of PVC window profiles at an angle of 90°

Single head welding possibility

Possibility of precise welding of profiles between 30°-180° on the left head

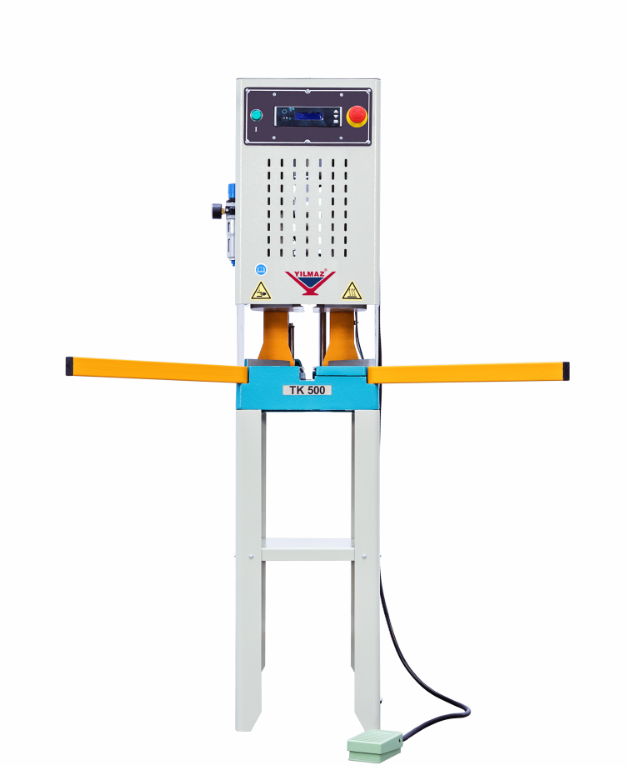

All parameters such as melting and welding time, welding pressure are set on the control panel independently

Continuous precision of welding quality by means of linear rails

Welding two corners of window frames or sash profiles are carried out in one cycle

User friendly with practical teflon change feature by means of the roller system

Saving of time by means of most practical mold change system in the market

Capable of adjusting the clamp and welding pressure according to the profile type

Adjusting the heat between 0-300°C via electronic thermostat

Practical setting of standard (2 mm) or seamless (0.2 mm for free of flashes) welding options

The movable right unit moves manually

After clamping the profiles, the welding is carried out automatically

The moveable right welding unit is equipped with a brake system

For safety reasons, the clamp pistons operate with low pressure

Equipped with two pcs. of support arms

STANDARD ACCESSORIES

1 set of sash welding mould with 60 mm of height

OPTIONAL ACCESSORIES

Special welding moulds on demand