GENERAL FEATURES

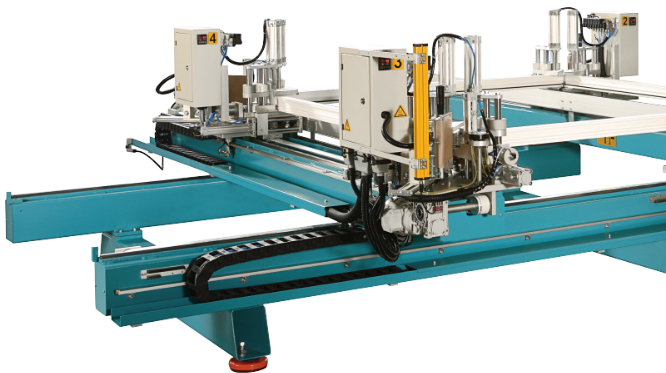

Fully automatic four corner welding of PVC window profiles at an angle of 90°

Welding of a complete window frame or sash in one cycle

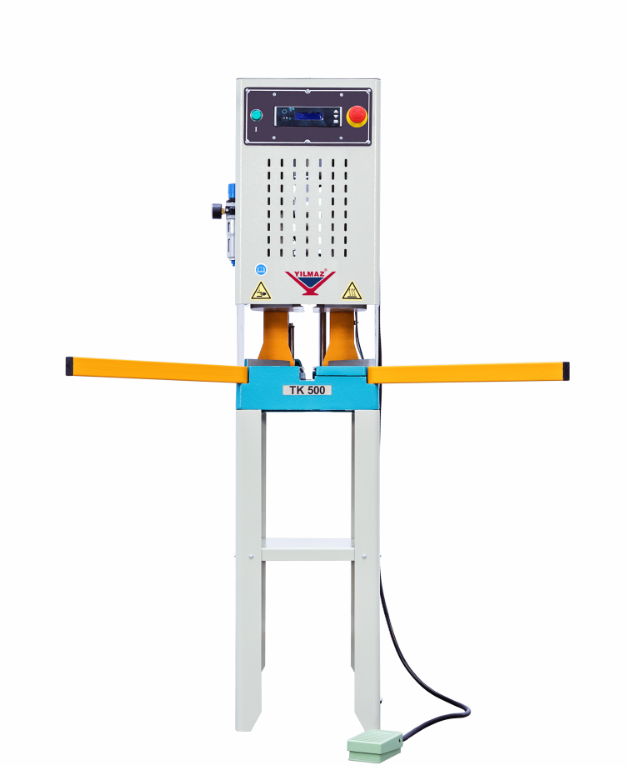

All profile related welding parameters are individually programmable

Parameters are set easily by means of 8’’ LCD colour touch screen

Automatic line can be made by combining with Cooling Unite (SA 250), Corner Cleaning Machine (CNC 608-610), Rotating Robot (SA 260) and Window Buffer Station (SA 251)

Automatically setting of standard (2 mm) or seamless (0.2 mm) welding options

Long-time of teflon using period by means of the roller system

Automatically discharging of the frames after welding operation

Saving of time by means of practical mould change system

Barcode scanner

Operator safety barrier

Adjusting the heat between 0-300°C via electronic thermocouple

Minimum welding measurement: 400 x 400 mm (see below sketch and tech. schema)

Maximum welding measurement: 3100 x 2700 mm (see below sketch and tech. schema)

Memory capacity to save up programs of 900 different profiles

STANDARD ACCESSORIES

Manual greasing pump

1 set of sash welding mould with 70 mm of height

1 set of adaptor for frame profile

OPTIONAL ACCESSORIES

SA 250 cooling unite

SA 251 window buffer station

CS 240 gasket pressing system

Welding fixture set

Special welding moulds on demand