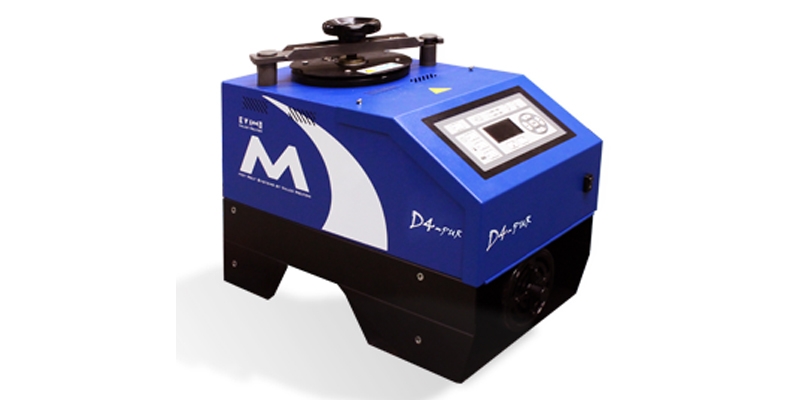

IsoMelt Mini Series can accommodate 2kg PUR standard slugs and work with up to 4 liters of adhesive. All units feature a fully integrated multi-functional controller that is accessible from a user-friendly screen, allowing for fast and easy configuration changes and providing ‘key-to-line’ capabilities.

Product Specifications

- Ideal for edge-banding, post-forming, bookbinding, product assembly and clear packaging.

- No cleaning is required, which eliminates the need for weekend shutdown.

- Swiveling tank lid allows for faster changes of PUR slugs, minimizing downtime.

- Optional pneumatic pressure regulation Integrated grammage control, accessible through a MFC controller, simplifies the operator’s programming tasks to eliminate product loss and downtime associated with incorrect coat weight adjustments.

- Optional lighting beacon and unit alarms to indicate low adhesive levels.

- Wide range of available options permits complete customization based on specific user needs.

| Technical Specifications | |

| Unit | Isomelt mini |

| Tank Capacity | 4L |

| Melting Capacity | 5 Kg/h (*) |

| Adhesives | PUR |

| Number of Pumps | 1 |

| Working Temperature | 30ºC – 230ºC |

| Electrical Connection | 230 V 3-phase Δ / 400 V 3-phase Y – 50/60 Hz |

| Max. Working Hydraulic Pressure | 100 Bar |

| Max. Working Viscosity | 100 000 cps |

| Max. Electrical Tank Consumption | 1200 W |

| Max. Pumping Capacity per Pump | max 48 Kg/h |

| Variable Speed | Yes |

| Grammage Control | Yes |

| Max. Electric Exits | 4 |

| Hydraulic Exits | 4 |

| Maximum output power (Channel 1 / Channel 2) | 2Х1800 W |

| Maximum output power (Channel 3 / Channel 4) | 2Х1400 W |

(*) Melt rate may vary depending on specific adhesive type.