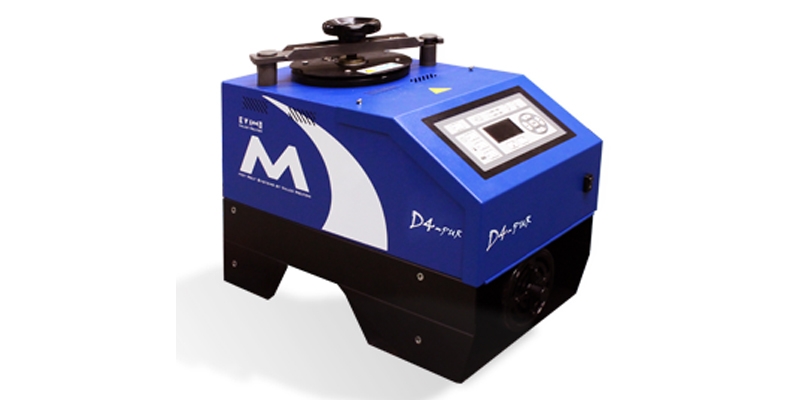

IsoMelt Series has been specifically designed to process reactive hot melts such as PUR. Fast and easy changes to EVA or APAO without adhesive degradation are no problem. The tank can accommodate 2 PUR standard bags, so that IsoMelt units can work with up to 40 liters of adhesive and meet the high production requirements of the woodworking, PVC and aluminum industries.

Product Specifications

- Integrated grammage control is accessible through our intuitive multi-function controller.

- Faster and safer maintenance and cleaning operations with innovative reclining tank and removable melting grid.

- Air-tight tank opening and blowing system.

- Dry blanket prevents moisture from reaching the adhesive.

- Lighting beacon for low adhesive levels and unit alarms.

| Technical Specifications | |

| Unit | IsoMelt Series Units |

| Tank Capacity | 40 L |

| Melting Capacity | 35 Kg/h (*) |

| Adhesives | PUR / EVA / APAO |

| Number of Pumps | max 2 |

| Working Temperature | 30 ºC – 230 ºC |

| Electrical Connection | 230 V 3-phase Δ / 400 V 3-phase Y – 50/60 Hz |

| Max. Working Hydraulic Pressure | 100 Bar |

| Max. Working Viscosity | 100 000 cps |

| Max. Electrical Tank Consumption | 6200 W |

| Max. Pumping Capacity per Pump | 48 |

| Maximum output power (Channel 1 / Channel 2) | 2000 W |

| Maximum output power (Channel 3 / Channel 4) | 1400 W |

(*) Melt rate may vary depending on specific adhesive type.