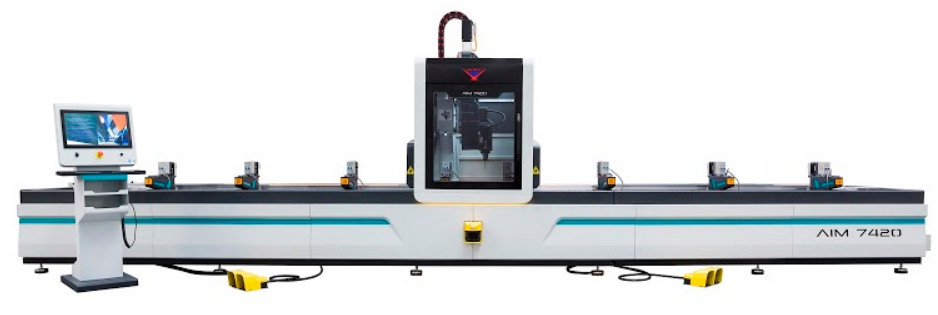

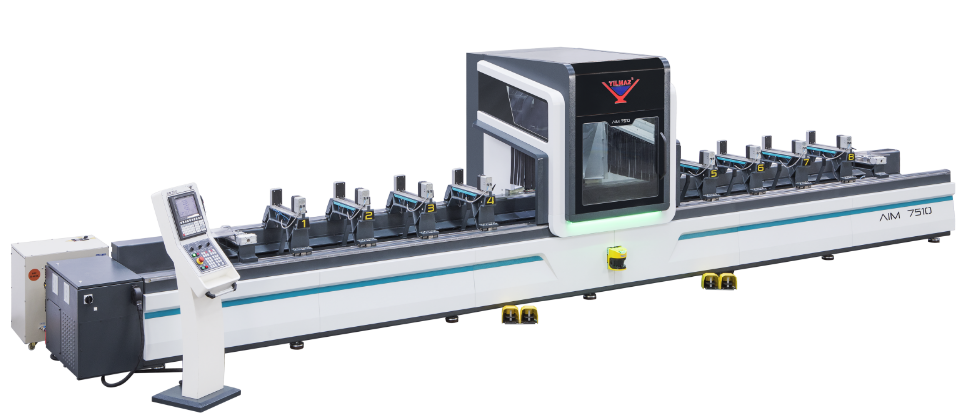

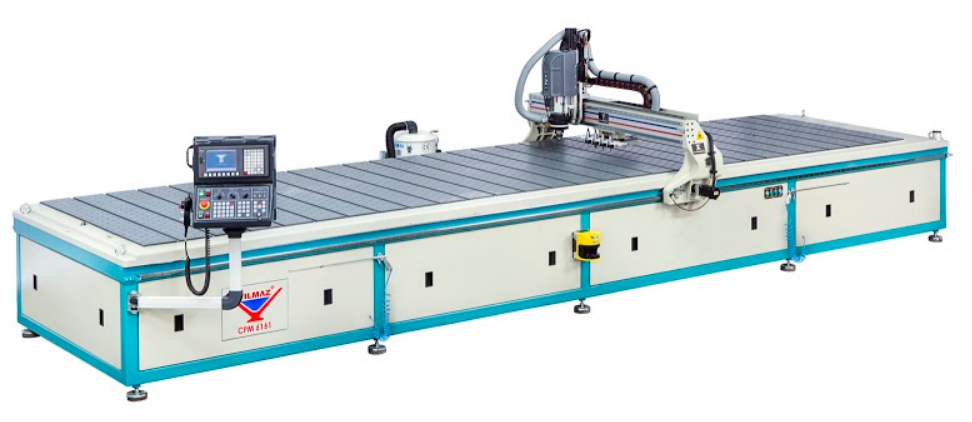

GENERAL FEATURES

• Designed for all kinds of drilling, grooving, notching, taping, etc. on aluminum profiles

• Uninterrupted machining property by means of the tandem mode to reduce the workpiece change time

• B&R automation system enabling CNC movement on 3 axis

• 8 tool magazine unit, 6 for cutter bits, 1 for aggregates and 1 for the saw blade

• Tapping feature on the open holes from M4 to M8 thread for 1 – 4 mm wall thickness (opt.)

• Special sound insulation cabinet around the machining center

• PLC controlled misty coolant spray system with 3 pcs of outlets

• 4 x automatic clamps used for grabbing the workpiece firmly

• 2 x pneumatic rests used for resetting the workpiece in X direction

• 15’’ color touch screen

• Fast programming using 8 preset macros

• Program import via USB flash memory stick

• Technical support via remote connection capability

• Standard ISO ‘G’ code programming language

• Multi-language support

• Operator safety barrier

• The LED lighting in the cabinet

OPTIONAL ACCESSORIES

• Automatic vise positioning via CAMPROX software

• Tapping chuck (up to M8)

• Automatic tool length measurement device

• Barcode-Scanner

• Chip removal conveyor belt

• Additional clamps

• Aggregate tools

• Cutter tools, milling saw, tool holder and collets

• Additional magazine unit with 8 tool capacity

• Design & Mnfg. of mold height apparatus for special profiles