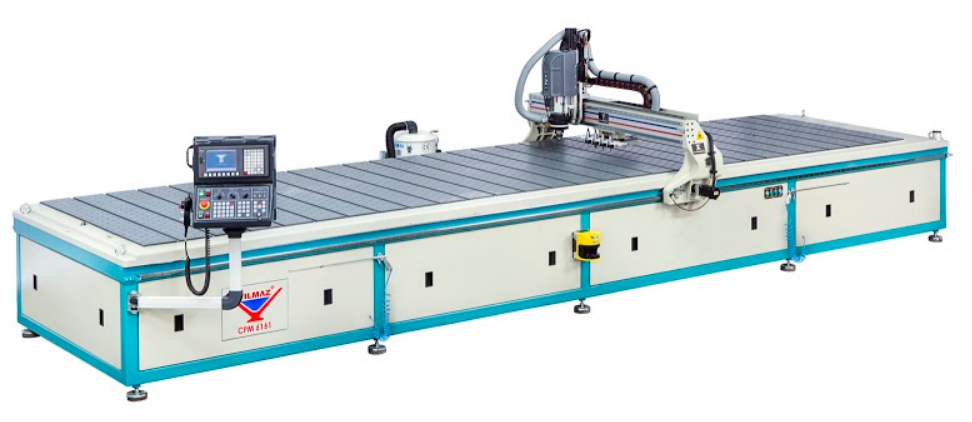

GENERAL FEATURES

Equipped with the automatic vacuum system concentrating the suction on the required area

3 axis CNC automation system

Solid steel construction of the body and dynamic performance gantry

Application of special cutting operations with minimum scrap by YILMAZ CAM software

Z-axis heat compensation system that adjusts the Z position of the cutter bit automatically considering to elongation on the spindle because of the thermal changes. (Patented)

High precision HSD spindle and internationally recognized components

Minimum tool change time with 5 stations automatic tool changer fixed on the gantry

4 pcs. of pneumatic pop-up stops enable you to locate the work plate accurately

Specially designed work table and powerful vacuum system to hold down the small pieces firmly

Air cushioning system to move the big size the plate on the table easily

An integrated tool length sensor ensures precise tool length measurements

Optimum dust extraction performance with specially designed vortex head and vacuum extractor

Multi-language support (Turkish and English)

PLC controlled tool cooling system

Specially designed control panel with colour display for CNC control

Handheld controller allows you to prove the job before running at speed

Easy program transfer with USB memory stick

Low maintenance with automatic central lubrication

Operator safety barrier

OPTIONAL ACCESSORIES

Special CAM programs via basic model of Alpha CAM software

Additional cutters

Additional ISO 30 tool holders

Additional collets

Additional chip removal extractor with 100 lt. of tank capacity