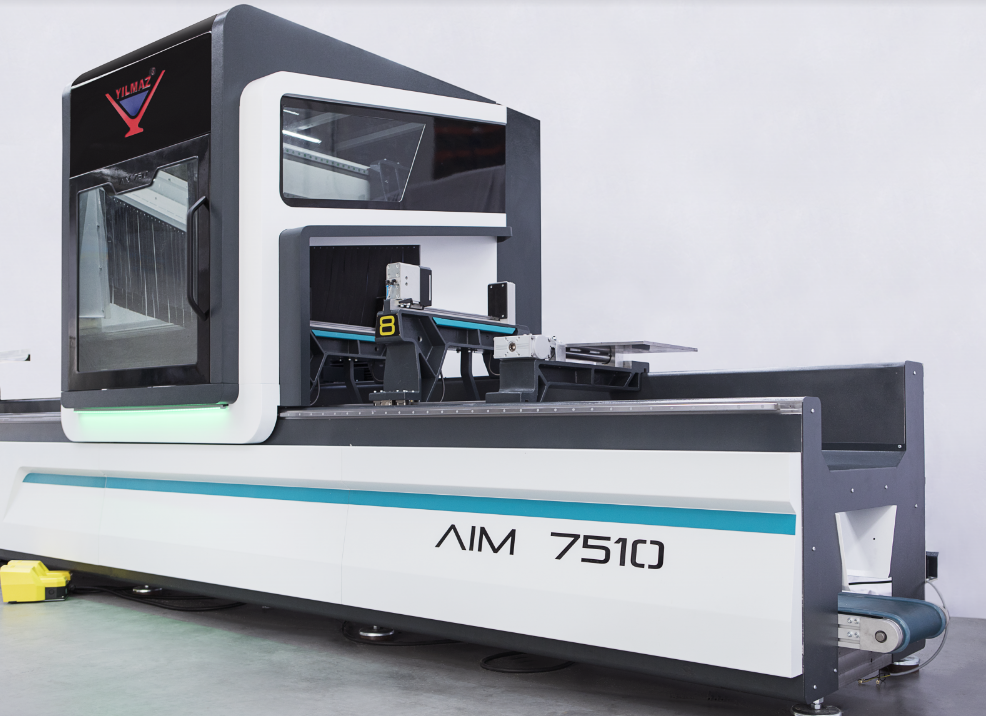

GENERAL FEATURES

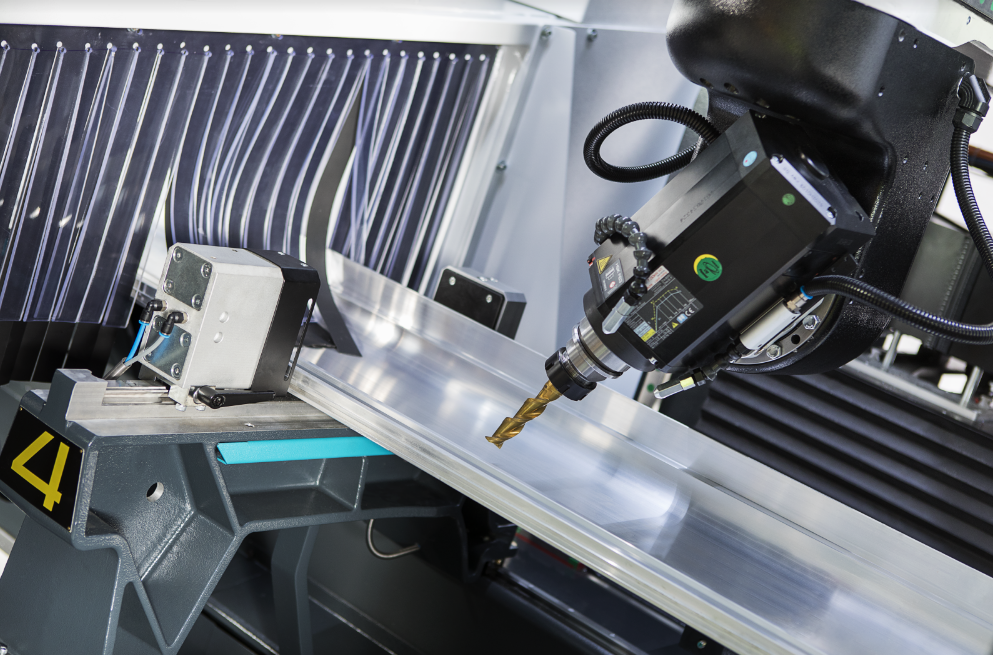

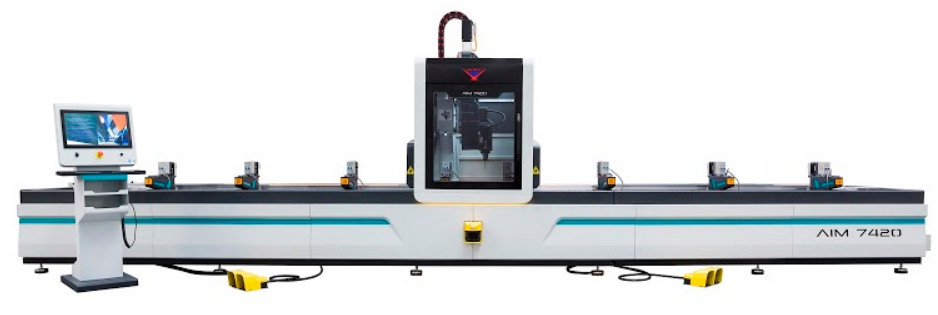

CNC automation system providing motion control at 5-axis

Uninterrupted machining property by means of the tandem mode to prevent waste of time

Ability of effective CAM programming by means of user friendly CAM PROX program

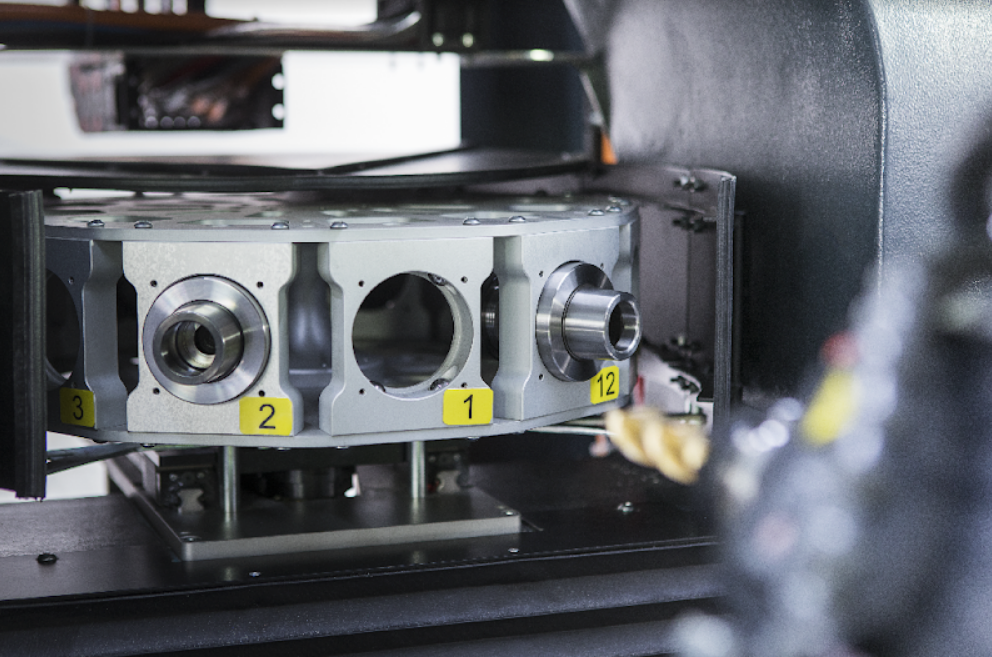

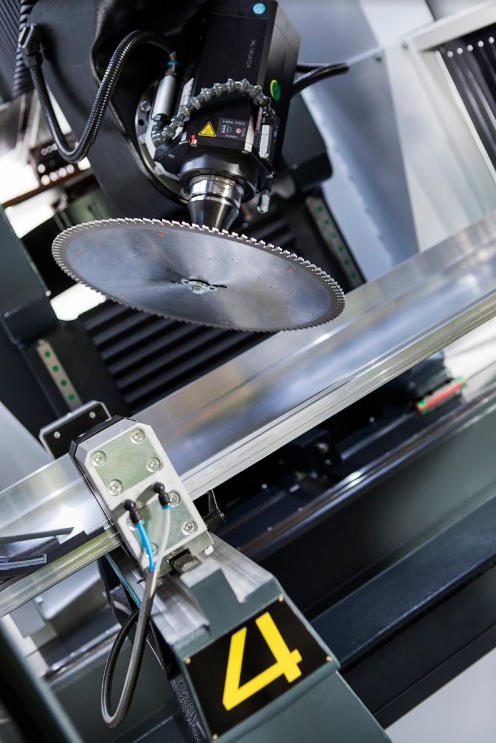

2 x separate magazine unit for 12 standard tools and 1 for saw blade with O350 mm

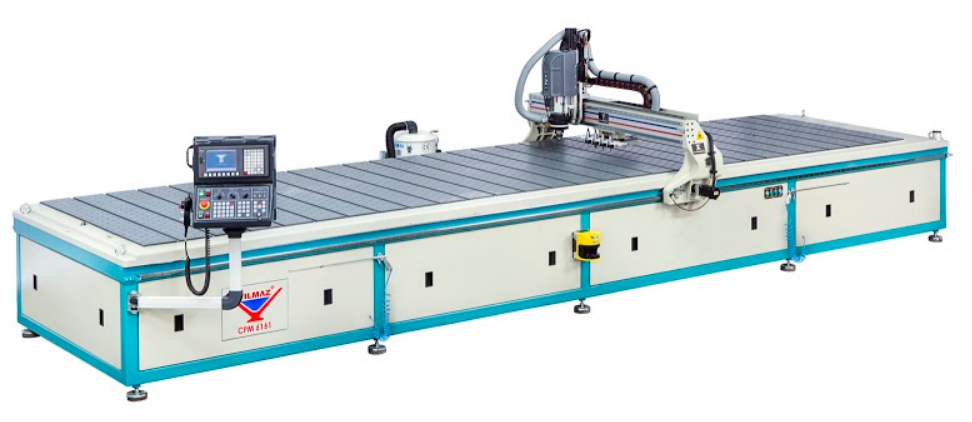

Solid steel construction of the body and dynamic performance gantry

Automatic clamp recognition and clamp positioning are available

Tapping feature from M4 to M8 for open holes and 1-4 mm of material thickness)(optional)

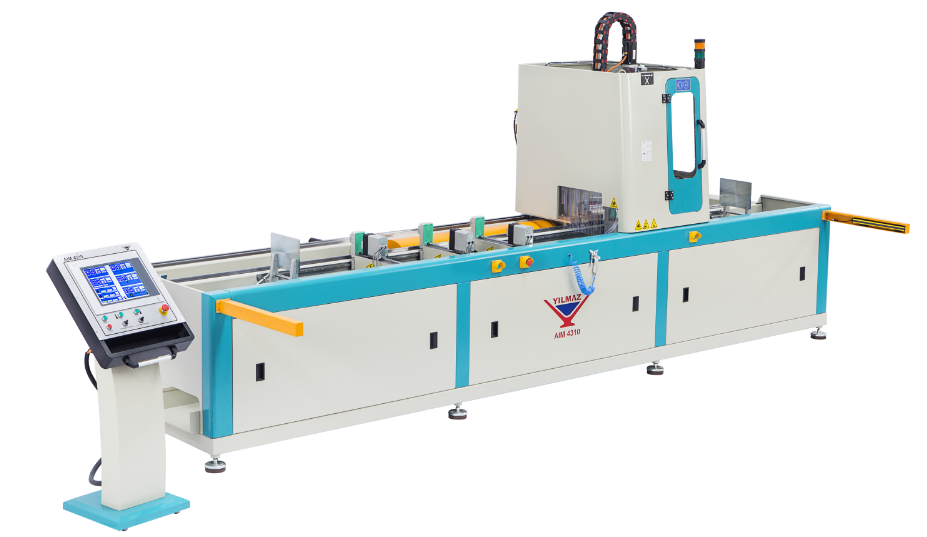

Special sound insulation cabinet around the machining center

High precision HSD spindle and internationally recognized components

CNC controlled spray tool lubrication system

8x automatic clamps are used for grabbing the workpiece firmly

2x pneumatic rests used for resetting the workpiece in X direction

Handheld controller allows you to prove the job before running at speed

Optimum operational safety guaranteed by 3-zone field scanner system

10’’ colour touch screen

Program import via USB flash memory stick

Standard ISO ‘G’ code programming language

Automatic central guide lubrication system

LED lighting in the cabinet

Multi-language support

OPTIONAL ACCESSORIES

Cutter tools, tool holders and collets set

CAD-EXTRACT software program for working on IGES files

Automatic tool length measurement device

Chip removal conveyor belt

Special saw blade kit

Additional options on demand