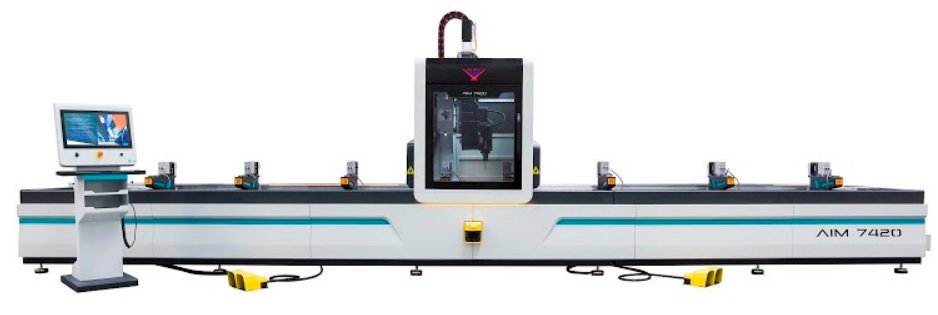

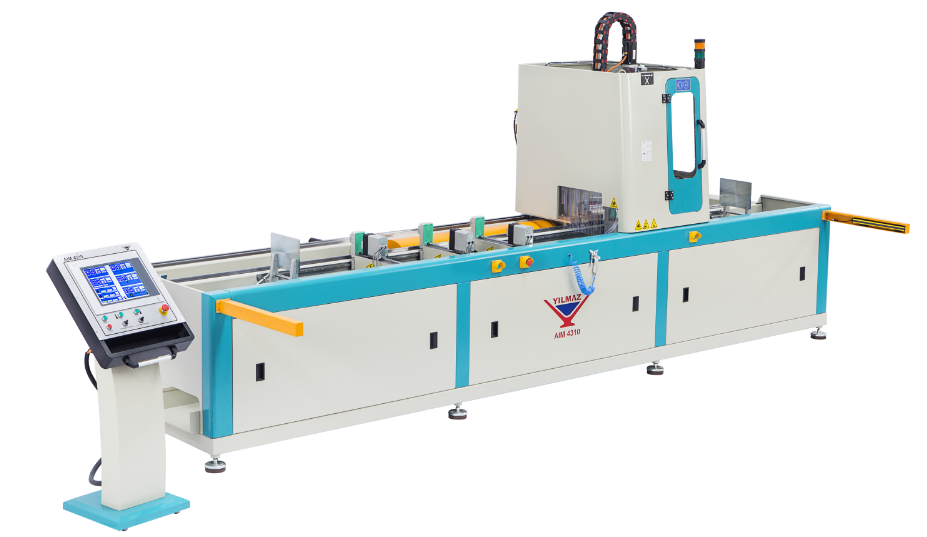

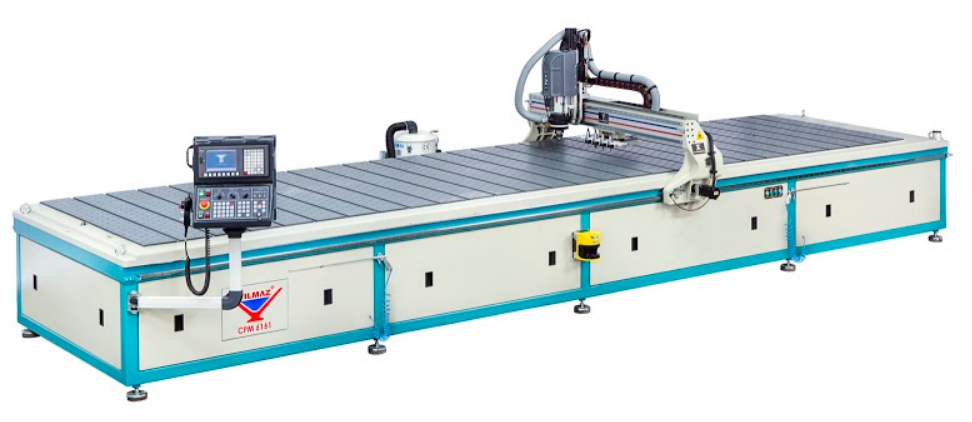

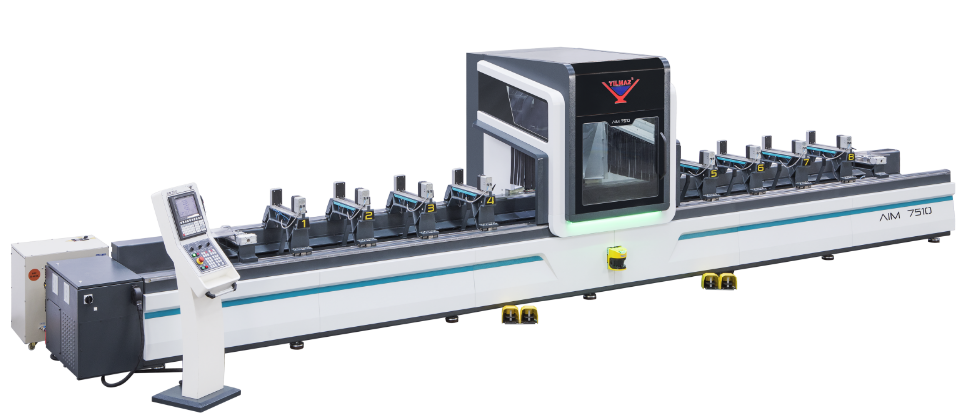

GENERAL FEATURES

Designed for all kinds of drilling, grooving, notching, taping etc. on aluminum profiles

Uninterrupted machining property by means of the two stations mode to reduce the workpiece change time (AIM 7320)

Tapping feature from M5 to M8 with the compensating chuck (opt.)

B&R automation system enabling CNC movement on 3 axis

8 tool magazine unit, 6 for cutter bits, 1 for aggregate and 1 for saw blade

Tapping feature on the open holes from M4 to M8 thread for 1-4 mm wall thickness (opt.)

Special sound insulation cabinet around the machining center

PLC controlled misty coolant spray system with 3 pcs of outlets

automatic clamps used for grabbing the work piece firmly

2 x pneumatic rests used for resetting the work piece in X direction

15’’ color touch screen

Fast programming using 8 preset macros

Program import via USB flash memory stick

Technical support capability via remote connection by computer

Standard ISO ‘G’ code programming language

Automatic cartridge lubrication system

Multi-language support

Operator safety barrier

LED lighting in the cabinet

OPTIONAL ACCESSORIES

Cutter tools, tool holders and collets set

CAD-EXTRACT software program for working on IGES files

Automatic tool length measurement device

Chip removal conveyor belt

Special saw blade kit

Additional options on demand