Hot Melt Adhesive Swift Lock 4780 on Polyurethane Base

Polyurethane-based hot melt glue has been specially developed for use in window technologies during the lamination of window PVC and aluminum profiles and window sills. It is suitable for both outdoor and indoor lamination

TECHNICAL SPECIFICATIONS:

| Lamination materials |

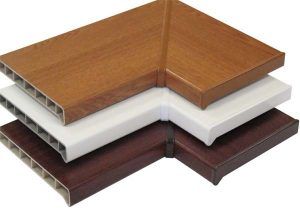

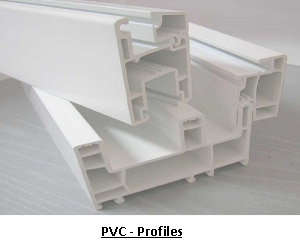

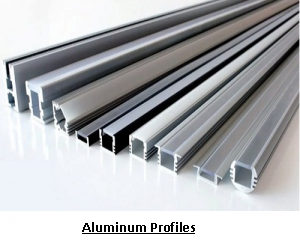

PVC – Profiles and Window sills Aluminum Profiles |

| Coatings | PVC films

Veneer CPL ( Continuous Pressure Laminates) |

| Base | Polyurethane prepolymer |

| Colour | Milk-White |

| Consistency | Solid substance |

| Density | 1,1 g/cm3 |

| Viscosity | at 120 °C (Brookfield, Thermosel System) – 38000 mPa.s |

| Application temperature | 120 – 140°C (in the melter up to 150 ° C) |

| Softening point | 75°C |

| Packaging | Package protected against humidity 2, 20 and 200 kg |

| Storage life | up to 12 months |

Applications:

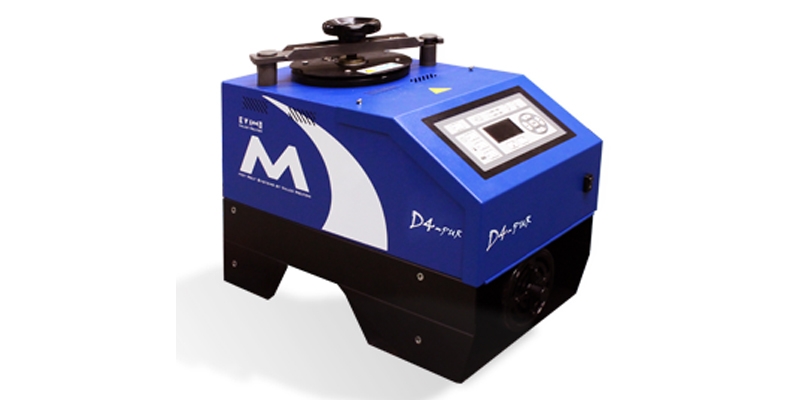

- Can be applied using rollers, nozzles, or other applicator systems.

- During lamination, maintain the temperature of metal surfaces at +40°C.

- The optimal PVC profile temperature before gluing should be +30°C – +35°C.

- For optimal results, materials must be clean, dry, and free from dust and contaminants.

- Full hardening of the adhesive is achieved after 1-3 days at 20°C and 65% relative humidity.

- After bonding, products are ready for further processing (cutting and trimming).

Storage Conditions:

- Store glue in a closed original package under cool and dry conditions at room temperature (+15°C to +30°C) with a minimum relative humidity of 30%.

- Protect from direct sunlight.

- Glue can be stored for at least 12 months without impacting its quality.

APPLICABLE MATERIALS FOR LAMINATION:

THE COATINGS USED FOR LAMINATION PROCESS: