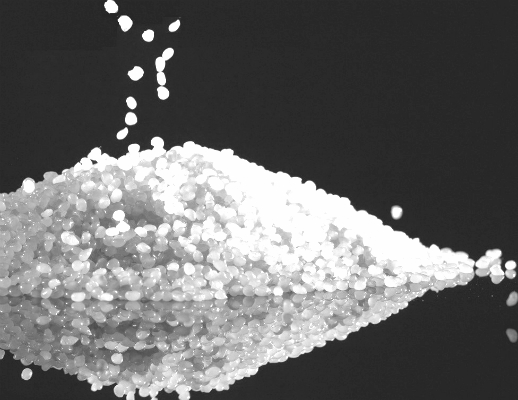

Hot melt adhesive EVOLUTION C-1800 on the base of synthetic resins

Latest-generation multi-purpose hot melt adhesive EVOLUTION C-1800 based on synthetic resins, is used in a wide range of packaging applications, such as carton sealing, tray erection and assembly of difficult substrates.

Depending on substrates, this product can allow bonds with heat resistance up to + 75 °C and cold resistance down to –25 °C. It is characterized by: very fast open and setting time, low density, improved adhesion properties and excellent thermal stability that allow to reduce the consumption at least 50%, depending on application, in comparison with other adhesives.

This product compared to EVA adhesive has improved thermal stability, stays constant in its viscosity, therefore no changes in the adhesion and in the processing quality, even by longer rests in the adhesive melting machines. Resistant to viscosity change resulting in clean machining hour after hour.

Advantages of hot melt adhesive EVOLUTION C-1800:

- Versability. Good adhesion to difficult substrates;

- Low consumption adhesive with extremely low density;

- Clean machining, no stringing and failing;

- Odour free and low fume emission;

- Extremely thermostable;

- Resistance to extreme temperatures;

- Flexibility at low temperatures;

- High heat resistance;

- Non-toxic;

- High Cohesion;

- Convenience of storage.

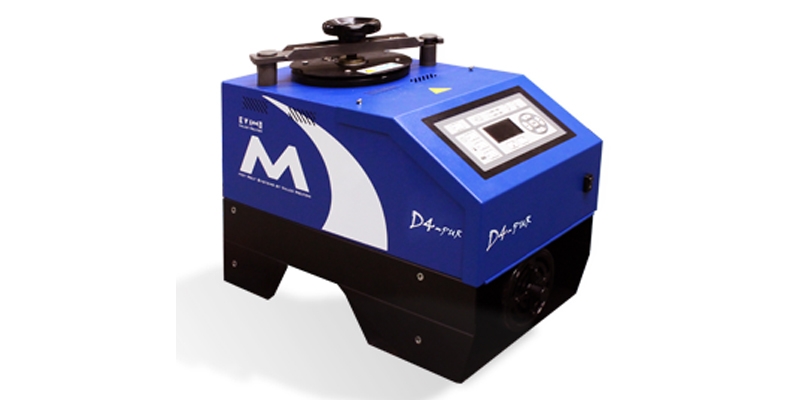

Application: can be used in nozzle, roller or other applicator system. Temperatures above 190 °C should be avoided. The equipment needs to be freed from EVA hot melt and cleaned since this product is not compatible with EVA based hot melts. During extended machine stops it is recommended to switch off the heating.

Storage conditions: glue should be stored in a closed original package under normal cool and dry storage conditions, should be protected from direct sunlight. In such conditions glue can be stored for at least 24 months without negative impact on it’s quality.

.jpg)