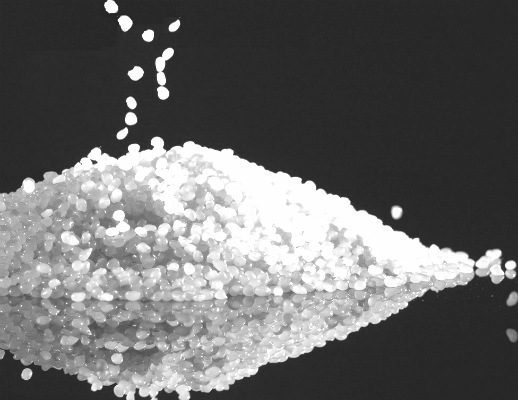

Hot melt adhesive EVOLUTION C 2700 on the base of polyolefin

Latest-generation multi-purpose hot melt adhesive EVOLUTION C2700 based on polyolefin and synthetic resins, is used in a wide range of packaging applications, such as carton sealing, tray erection and assembly of difficult substrates. One adhesive can perform in several different applications. It has excellent adhesion to a wide range of difficult substrates.

Depending on substrates, this product can allow bonds with heat resistance up to + 70 °C and cold resistance down to –25 °C. It is characterized by: very fast open and setting time, low density, improved adhesion properties and excellent thermal stability that allow to reduce the consumption at least 50%, depending on application, in comparison with other adhesives.

Adhesive run clean, remain stable in the tank and eliminate char and gel cost with downtime, consumable and preventive maintenance reduce significantly. After 96 hours heated up to 170 °C adhesive maintains its light color.

This product compared to EVA adhesive has an improved thermal stability, stays constant in its viscosity, therefore no changes in the adhesion and in the processing quality, even by longer rests in the adhesive melting machines. Resistant to vescosity change resulting in clean machining hour after hour.

Hot melt EVOLUTION C 2700 is used for:

- Bonding of flour bags, boxes for tea and refined sugars;

- Assembly and closure of cardboard and corrugated base paper;

- Closure of paper bags and packages;

- Manufacturing and closure of various trays, wrap-arounds, folding boxes, carton and case sealing for food, beverages and other consumer and industrial boxes;

- Gluing of paper bag handles and longitudinal seams;

- Bonding of wrapping paper and even cardboard with coated or varnished surface;

- Manufacturing of Tetra-Pak packages.

Properties of hot melt adhesive EVOLUTION C2700:

- Versability. Good adhesion to difficult substrates;

- Low consumption adhesive with extremely low density;

- Clean machining, no stringing and failing;

- Odour free and low fume emission;

- Extremely thermostable;

- Resistance to extreme temperatures;

- Flexibility at low temperatures;

- High heat resistance;

- Not-toxic;

- High Cohesion;

- Low viscosity;

- Low adhesive cost;

- Long storage life;

- Convenience of storage.

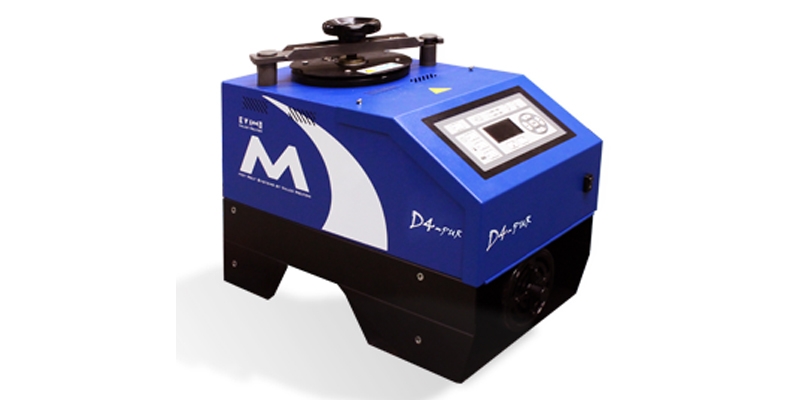

Application: can be used in nozzle, roller or other applicator system. Temperatures above 190 °C should be avoided. The equipment needs to be freed from EVA hot melt and cleaned since this product is not compatible with EVA based hot melts. During extended machine stops it is recommended to switch off the heating.

Storage conditions: glue should be stored in a closed original package under normal cool and dry storage conditions, should be protected from direct sunlight. In such conditions glue can be stored for at least 24 months without negative impact on it’s quality.

.jpg)