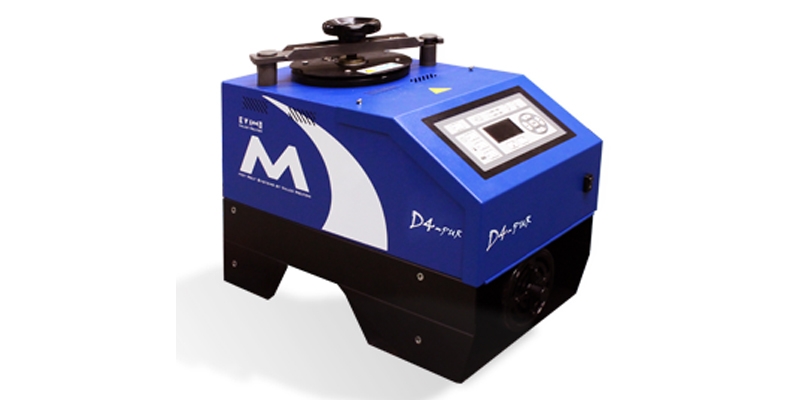

Hot Melt Adhesive Swift Lock 4955 M on Polyurethane Base

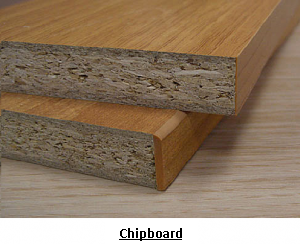

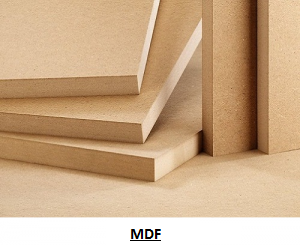

Polyurethane-base hot melt adhesive Swift Lock 4955 M is used for the lamination of profile products made of aluminum, PVC, and wood, such as chipboard, MDF, plywood with decorative PVC films, veneer, CPL (Continuous Pressure Laminate – Melamine), and other materials.

Characteristics:

- Light-colored hot melt adhesive with excellent machining characteristics

- Very good heat stability and heat resistance

- Fast setting and high initial tack

- High viscosity and adhesion, allowing coverage of thick, rigid, problem films, and veneer

- Increased heat resistance and moisture resistance after curing

TECHNICAL SPECIFICATIONS:

| Lamination materials | Chipboard, MDF, Plywood |

| Coatings | PVC films, Veneer, CPL (Continuous Pressure Laminat) |

| Base | Polyurethane |

| Colour | Yellowish |

| Consistency | Solid substance |

| Density | 1.25 g / sm3 |

| Viscosity | at 120 °C (Brookfield, Thermosel System) – 60000 mPa.s

at 140 °C (Brookfield, Thermosel System) – 34000 mPa.s |

| Open time | Approx. 20-50 sec |

| Application temperature | 120 – 160°C (in the melter up to 170°C) |

| Packaging | Package protected against humidity 2, 20 and 200 kg |

| Shelf life | Up to 12 months |

Applications:

- Can be applied using rollers, nozzles, or other applicator systems.

- During lamination, it is recommended that the temperature of metal surfaces be maintained at +40°C.

- In the case of PVC profiles, heating significantly improves the quality of adhesion and helps reduce glue consumption. The optimum profile temperature before gluing should be between +30°C and +35°C.

- For optimal results, bonded materials must be clean, dry, and free from dust and grease.

- Full hardening of the adhesive is achieved after 5-7 days at 20°C and 65% relative humidity.

- Immediately after mechanical bonding, the products are ready for further processing (cutting and formatting).

- Equipment for glue melting should be protected from atmospheric moisture.

Storage Conditions:

- Glue should be stored in a closed original package under cool and dry conditions at room temperature (+15°C to +30°C) with a minimum relative humidity of 30%.

- Protect from direct sunlight.

- Under these conditions, glue can be stored for at least 12 months without affecting its quality.

APPLICABLE MATERIALS FOR LAMINATION:

THE COATINGS USED FOR LAMINATION PROCESS: