Hot melt adhesive Swift Lock 9515 on the polyurethane base

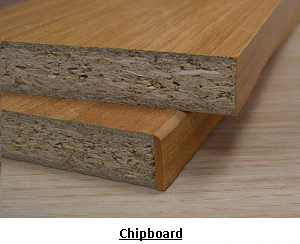

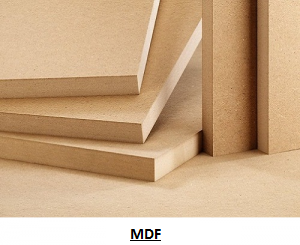

Polyurethane base hot-melt, used for lamination of panels based on wood: chipboard, MDF, plywood, polyurethane, polystyrene by decorative PVC films, veneer, CPL (Continuous Pressure Laminaters), HPL ( High Pressure Laminates) and other materials.

The curing of the adhesive occurs due to atmospheric humidity and special embedded adhesive components. After curing, the adhesive has excellent mechanical properties and provides high thermal stability and water resistance. This adhesive has a long open time and at the same time provides high productivity.

TECHNICAL SPECIFICATIONS:

| Lamination materials | Chipboard MDF Plywood |

| Coatings | PVC films Veneer CPL (Continuous Pressure Laminates) HPL( High Pressure Laminates) |

| Base | Polyurethane |

| Colour | Yellowish |

| Consistency | Solid substance |

| Density | 1,10 g/cm3 |

| Viscosity | at 130 °C (Brookfield, Thermosel System) – 17000 mPa.s |

| Application temperature | 130 – 150 ° C (in the melter up to 160 ° C) |

| Open time | 5 min, depending on materials |

| Packaging | Package protected against humidity, 190 kg. |

Applications: can be applied in rollers or nozzles or another applicator system. During lamination it is recommended that the temperature of metal surfaces should be maintained at +40°C. For the optimum results, materials which is bonded must be clean and dry, free from dust and grease. Full hardening of the adhesive is achieved after 5-7 days, depending on the humidity and temperature. Immediately after mechanical bonding, products are ready for further processing (cutting and formating). Equipment for glue melting should be protected from atmospheric moisture.

Storage conditions: glue should be stored in a closed original package under normal cool and dry storage conditions at room temperature from + 15 ° C to + 30 ° C with a minimum relative humidity of 30%, should be protected from direct sunlight. In such conditions, glue can be stored for at least 12 months without a negative impact on its quality.

APPLICABLE MATERIALS FOR LAMINATION:

THE COATINGS USED FOR LAMINATION PROCESS: