Hot melt adhesive FL80 on the base of polyolefin

New generation hot-melt suitable for wrapping highly impregnate paper foils, laminates, thermoplastic foils (PP, PE, PVC) to solid wood, chipboard and MDF.

Unfilled hot-melt with no mineral fillers, low viscosity and high resistance to heat. It is characterized by: low density, high glue mileage, good wetting on substrates, very good adhesion strength, excellent surface smoothness and quick-melting, highly suitable for high-speed equipment. Heat resistance in customer´s materials: up to 70°C.

Hot melt FL80 is used for:

- Bonding decorative paper or wood veneer on MDF, PVC or wood profiles;

- Lining of MDF or wood profiles with decorative paper or wood veneer;

- Bonding thermoplastic foils on MDF or solid wood profiles.

Properties and benefits of hot melt adhesive FL80:

- Allow high speed bonding;

- High-Yield Adhesive;

- Versatility, bonding a wide range of substrates;

- Low odour and low fume emission;

- Clean running: no stringing or blocking coating heads;

- Good resistance against moisture, humidity and heat;

- Excellent adhesion strength;

- Good adhesion on difficult substrates;

- Good thermal stability;

- Excellent surface smoothness;

- Long storage life;

- Convenience of storage.

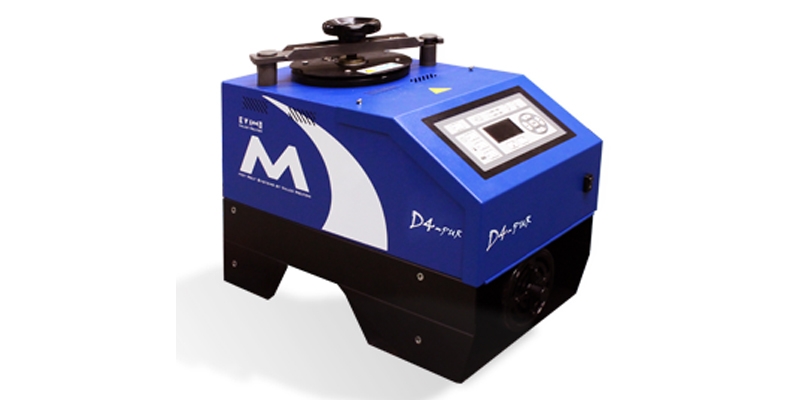

Application: can be used in nozzle, roller or other applicator system. Recommended working temperature is 145 – 180°C. During extended machine stops it is recommended to switch off the heating.

Storage conditions: glue should be stored in a closed original package under normal cool and dry storage conditions and protected from direct sunlight. In such conditions glue can be stored for at least 24 months without negative impact on its quality.